Warehouse Design

Warehouse Design: Maximizing Efficiency and Storage Solutions

Warehouse design plays a crucial role in the efficiency of storage and distribution. A well-planned layout can save time and reduce costs.

Good warehouse design means more than just placing shelves and aisles. It involves strategic planning to maximize space, improve workflow, and ensure safety. This type of design can impact productivity and customer satisfaction. We’ll explore the essential elements of warehouse design.

You’ll learn how to create a layout that meets your needs and boosts efficiency. Whether you are starting from scratch or rethinking an existing space, these insights will be valuable. Let’s dive into the key aspects of effective warehouse design.

Importance Of Warehouse Design

Warehouse design is vital for any business. It ensures smooth operations and maximum efficiency. A well-designed warehouse helps in better storage and faster retrieval of goods. This leads to improved productivity and customer satisfaction.

Shelving Systems

Shelving systems are a key part of warehouse design. They help in organizing products systematically. Good shelving allows easy access to items. It also helps in saving space and keeping the warehouse tidy.

Material Handling

Material handling involves moving goods within the warehouse. Efficient material handling reduces time and labor costs. It ensures that products are safe and undamaged. Using the right equipment is crucial for effective material handling.

Workflow Design

Workflow design is about planning the movement of tasks. A well-planned workflow ensures that tasks are completed smoothly. It helps in reducing delays and improving efficiency. Proper workflow design also minimizes errors in the warehouse.

Space Utilization

Space utilization is making the best use of available space. Proper space utilization prevents clutter and maximizes storage. It helps in keeping the warehouse organized. This leads to faster picking and packing of items.

Inventory Management

Inventory management is tracking and controlling stock levels. Effective inventory management prevents overstocking and stockouts. It helps in maintaining the right balance of products. Good inventory management leads to better customer service.

Logistics Efficiency

Logistics efficiency is about optimizing the movement of goods. It ensures timely delivery of products. Efficient logistics reduce transportation costs and improve service levels. This leads to higher customer satisfaction.

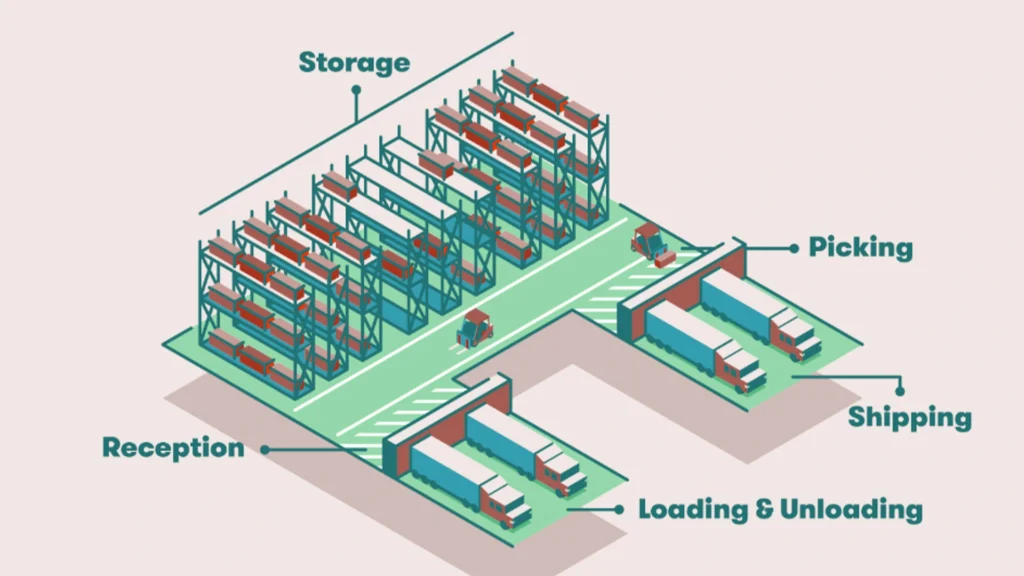

Warehouse Layout

Warehouse layout is the arrangement of storage and work areas. A good layout improves workflow and space utilization. It helps in reducing travel time and increasing productivity. Proper layout design ensures smooth operations in the warehouse.

Picking Systems

Picking systems are methods used to collect items for orders. Efficient picking systems reduce errors and speed up the process. They help in improving order accuracy and customer satisfaction. Good picking systems are essential for a well-run warehouse.

Safety Regulations

Safety regulations ensure the well-being of workers. Following safety rules prevents accidents and injuries. It creates a safer working environment. Compliance with safety regulations is crucial for any warehouse.

Storage Optimization

Storage optimization is about using storage space effectively. It helps in maximizing the capacity of the warehouse. Proper storage optimization reduces clutter and improves accessibility. This leads to faster and more efficient operations.

Key Design Principles

Designing a warehouse involves many important principles. These principles ensure efficient use of space and smooth workflow. Understanding these principles can help in creating a functional and productive warehouse environment.

Space Utilization

Effective space utilization is crucial in warehouse design. Maximizing available space helps in storing more goods and reducing costs. Several strategies can be used to achieve this:

- Vertical Storage: Utilize vertical space with tall shelves and racks.

- Narrow Aisles: Design narrow aisles to fit more storage units.

- Efficient Layout: Arrange storage areas logically for easy access.

- Multi-purpose Areas: Use areas for multiple functions when possible.

These strategies help in better organization and access to inventory. Avoiding wasted space is key in maintaining an efficient warehouse. Proper planning and layout adjustments can significantly improve space utilization.

Workflow Optimization

Optimizing workflow is another vital principle in warehouse design. Smooth and efficient workflow reduces delays and increases productivity. Key points to consider include:

- Clear Pathways: Ensure clear and unobstructed pathways for movement.

- Logical Layout: Place high-demand items closer to the dispatch area.

- Automation: Use technology to automate repetitive tasks.

- Safety Measures: Implement safety protocols to prevent accidents.

A well-optimized workflow ensures quick and accurate order processing. Reducing travel time within the warehouse is crucial. This can be achieved by strategic placement of goods and efficient layout design. Attention to these details can greatly enhance overall efficiency.

Types Of Warehouse Layouts

Warehouse design is critical for optimizing space and efficiency. Different layouts suit various needs and purposes. Choosing the right one can improve productivity and reduce costs. Two popular layouts are U-Shaped and L-Shaped. Each has unique benefits and considerations.

U-shaped

The U-Shaped warehouse layout forms a “U” shape. This setup is common in many industries. It allows for easy movement of goods.

Advantages:

- Efficient flow of goods from receiving to shipping.

- Reduced travel time for workers.

- Better space utilization with clear zones for tasks.

This layout works well for high-volume operations. Products move in a loop, minimizing congestion. Loading and unloading areas are separate, improving workflow.

Feature | Benefit |

Clear Zones | Less Confusion |

Loop Movement | Improved Efficiency |

Ideal for: Large warehouses with high stock turnover.

L-shaped

The L-Shaped warehouse layout forms an “L” shape. This design is versatile and can fit into various building shapes.

Advantages:

- Flexibility in design to fit different spaces.

- Separate areas for different functions.

- Improved safety with clear paths for movement.

This layout is useful for businesses with diverse products. It allows for easy separation of goods. The design can help in organizing different processes efficiently.

Feature | Benefit |

Separate Areas | Better Organization |

Flexible Design | Adaptable to Space |

Ideal for: Smaller warehouses or those with varied products.

Storage Solutions

Warehouse design plays a crucial role in ensuring efficient storage and accessibility. Good storage solutions make a significant difference in the smooth operation of a warehouse. Effective designs help in maximizing space, improving organization, and enhancing productivity. This blog post will explore two essential storage solutions: pallet racking and shelving systems.

Pallet Racking

Pallet racking is a popular storage solution in many warehouses. It provides a robust and flexible way to store large quantities of goods. Here are some key benefits of using pallet racking:

- Maximizes vertical space: Pallet racking takes advantage of the vertical space in the warehouse.

- Improves accessibility: Pallets can be easily accessed using forklifts.

- Enhances organization: Goods can be stored in a systematic manner.

- Increases safety: Properly installed racks improve the safety of stored items.

There are different types of pallet racking systems:

Type | Description |

Selective Racking | Most common type, easy access to all pallets. |

Drive-In Racking | High-density storage, fewer aisles needed. |

Push-Back Racking | Pallets are stored on a slope, easy retrieval. |

Each type has its advantages. Selective racking offers easy access. Drive-in racking saves space. Push-back racking ensures quick retrieval. Choosing the right system depends on the specific needs of the warehouse.

Shelving Systems

Shelving systems are another essential storage solution. They are ideal for smaller items and manual picking operations. Shelving systems provide several benefits:

- Versatility: Suitable for various types of products.

- Easy installation: Can be quickly set up and reconfigured.

- Accessibility: Items are easily reachable by hand.

Common types of shelving systems include:

Type | Description |

Metal Shelving | Durable and strong, good for heavy items. |

Wire Shelving | Allows air circulation, prevents dust build-up. |

Plastic Shelving | Lightweight, resistant to moisture and chemicals. |

Metal shelving is perfect for heavy items. Wire shelving is great for cleanliness. Plastic shelving works well in damp environments. The choice of shelving system depends on what is being stored and the conditions of the warehouse.

Technology Integration

Warehouse design is crucial for efficient operations. Integrating technology in warehouses has become essential. It helps streamline processes, reduce errors, and improve productivity. Modern warehouses use various technologies to stay competitive. This blog discusses the importance of Technology Integration in Warehouse Design.

Warehouse Management Systems

Warehouse Management Systems (WMS) are vital for modern warehouses. They help manage inventory and control operations efficiently. A good WMS offers many benefits:

- Enhanced inventory accuracy: Reduces errors and ensures correct stock levels.

- Improved order fulfillment: Speeds up the picking and packing process.

- Better space utilization: Maximizes warehouse storage capacity.

- Real-time data access: Provides up-to-date information on inventory and operations.

WMS also helps with task management and labor planning. It assigns tasks to workers based on their skills and availability. This improves productivity and reduces downtime. Many warehouses use advanced WMS with RFID and barcode technology. These systems track inventory movement and location accurately.

A comparison of popular WMS solutions can help in selecting the right one:

Feature | Solution A | Solution B | Solution C |

Inventory Accuracy | 99% | 98% | 97% |

Order Fulfillment | Fast | Moderate | Slow |

Space Utilization | High | Medium | Low |

Choosing the right WMS can greatly impact warehouse efficiency. It is important to evaluate features and select the best fit for your needs.

Automation Tools

Automation tools play a key role in modern warehouses. They help streamline operations and reduce manual labor. Common automation tools include:

- Automated Guided Vehicles (AGVs): Transport goods within the warehouse.

- Robotic Picking Systems: Automate the picking process, increasing speed and accuracy.

- Conveyor Systems: Move products efficiently from one area to another.

- Automated Storage and Retrieval Systems (AS/RS): Store and retrieve items with precision.

These tools help reduce errors and improve productivity. AGVs, for example, can work around the clock without fatigue. Robotic picking systems ensure accurate order fulfillment. This reduces the chances of sending wrong items to customers. Conveyor systems and AS/RS also help in optimizing space and improving workflow.

Investing in automation tools brings long-term benefits. It reduces labor costs and minimizes human errors. The following table shows the advantages of different automation tools:

Tool | Benefit |

AGVs | Continuous operation, reduced labor costs |

Robotic Picking Systems | High accuracy, fast order fulfillment |

Conveyor Systems | Efficient product movement |

AS/RS | Optimized space, precise storage |

Automation tools are essential for a modern warehouse. They improve efficiency and ensure smooth operations.

Safety Considerations

Warehouse design plays a crucial role in ensuring the safety and efficiency of operations. Safety considerations are paramount to prevent accidents and ensure a safe working environment. Proper planning and implementation of safety measures can significantly reduce risks and enhance productivity. This blog will discuss key aspects of equipment safety and emergency protocols in warehouse design.

Equipment Safety

Ensuring equipment safety is vital in a warehouse. Proper handling and maintenance of equipment prevent accidents and injuries.

Key aspects of equipment safety include:

- Regular maintenance: Routine checks and servicing of equipment like forklifts and conveyors ensure they function correctly.

- Training: Workers must receive proper training to operate equipment safely.

- Protective gear: Providing safety gear such as helmets, gloves, and safety shoes reduces injury risks.

- Clear signage: Labeling hazardous areas and equipment helps in avoiding accidents.

Additionally, having a dedicated area for equipment storage can prevent clutter and potential hazards. Organizing tools and equipment properly increases safety and efficiency.

Emergency Protocols

Having well-defined emergency protocols is essential in any warehouse. These protocols ensure quick and effective responses to emergencies.

Important emergency protocols include:

- Fire safety: Install fire extinguishers and alarms. Conduct regular fire drills.

- First aid kits: Keep first aid kits accessible. Train staff in basic first aid.

- Evacuation plans: Clearly mark exits. Display evacuation routes and conduct regular drills.

- Emergency contacts: Maintain an updated list of emergency contacts and ensure all staff know where to find it.

Communication systems should be in place to alert workers immediately in case of an emergency. Quick communication can save lives and minimize damage.

Regularly reviewing and updating emergency protocols ensures preparedness for any situation. Staff should be familiar with these protocols and trained to act swiftly and correctly.

Sustainability In Design

Designing a warehouse involves many factors. One key element is sustainability. Sustainable warehouse design focuses on reducing environmental impact. This includes using energy-efficient systems and eco-friendly materials. Such designs can also lower operating costs. It’s a win-win for businesses and the planet.

Energy Efficiency

Energy efficiency is crucial in warehouse design. It helps in cutting down energy usage and costs. One effective way is using LED lighting. LED lights consume less power and last longer than traditional bulbs. This reduces the need for frequent replacements.

Another method is installing skylights. Skylights provide natural light during the day. This reduces the need for artificial lighting. It also improves the work environment for employees. Better lighting can lead to higher productivity.

Insulating the warehouse is also important. Proper insulation keeps the warehouse cool in summer and warm in winter. This means less energy is needed for heating and cooling. It also ensures a comfortable working environment.

Here is a table showing some energy-efficient practices:

Practice | Benefit |

LED Lighting | Lower energy use and longer lifespan |

Skylights | Natural light reduces artificial lighting needs |

Insulation | Maintains temperature and reduces energy costs |

Green Materials

Using green materials is another aspect of sustainable warehouse design. These materials are eco-friendly and often recyclable. One example is recycled steel. It’s durable and has a lower environmental impact than new steel. Using recycled steel helps in conserving natural resources.

Bamboo is another great material. Bamboo grows quickly and is very strong. It can be used for flooring, shelves, and other structures. Bamboo’s fast growth means it can be replenished quickly, making it a sustainable choice.

Low-VOC paints are also important. VOCs (Volatile Organic Compounds) can be harmful to health. Low-VOC paints reduce the release of these compounds. This improves indoor air quality and creates a safer environment for workers.

Here are some green materials used in warehouses:

- Recycled Steel

- Bamboo

- Low-VOC Paints

Future Trends

Warehouse design is changing fast. New trends are shaping the future. These changes aim to improve efficiency, safety, and productivity. One major trend is smart warehousing. This trend uses technology to improve operations. Let’s explore how smart warehousing is making a difference.

Smart Warehousing

Smart warehousing is becoming popular. It uses advanced technology. This helps in managing warehouse operations. Key technologies include IoT, AI, and robotics. These technologies improve inventory management. They also increase accuracy and speed.

Here are some benefits of smart warehousing:

- Improved Accuracy: Automated systems reduce human error.

- Higher Efficiency: Robots and AI speed up processes.

- Better Inventory Management: Real-time tracking of goods.

- Cost Savings: Reduced labor costs and waste.

Smart warehousing also enhances safety. Robots handle dangerous tasks. This reduces the risk of injury. Employees can focus on less risky jobs.

Here is a comparison of traditional and smart warehousing:

Feature | Traditional Warehousing | Smart Warehousing |

Inventory Management | Manual | Automated |

Accuracy | Prone to errors | High accuracy |

Efficiency | Slower processes | Faster processes |

Safety | More risks | Fewer risks |

Smart warehousing is the future. It offers many benefits. Businesses can save time and money. They can also improve safety and efficiency. This trend is set to grow in the coming years.

Frequently Asked Questions

What Are The Key Elements Of Warehouse Design?

Key elements include layout, storage systems, workflow optimization, safety measures, and accessibility. Good design improves efficiency and productivity.

How Does Warehouse Layout Impact Efficiency?

A well-planned layout reduces travel time, streamlines processes, and minimizes errors. This boosts overall efficiency and productivity.

Why Is Safety Important In Warehouse Design?

Safety ensures the well-being of workers. It also prevents accidents, reduces downtime, and lowers costs related to injuries.

What Role Does Technology Play In Warehouse Design?

Technology improves inventory management, tracking, and automation. This enhances accuracy, efficiency, and helps in better space utilization.

Conclusion

A well-designed warehouse boosts efficiency and productivity. It optimizes space and workflow. A good layout saves time and reduces costs. Proper shelving and storage systems enhance organization. Lighting and safety measures ensure a better work environment. Invest in technology for better inventory management.

Regularly review and update your design. This keeps operations smooth and effective. The right design transforms a warehouse into a powerful asset.